Flatness and contour measurement of sheets

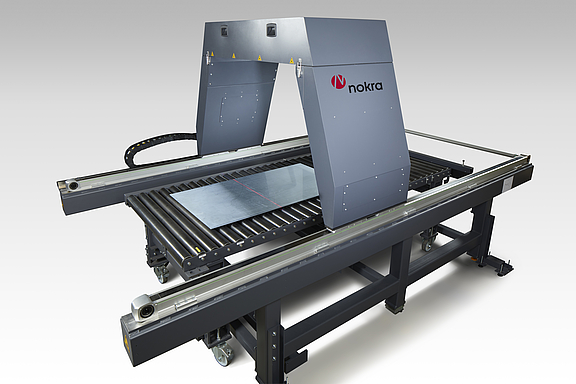

alpha.fi compact / Laser measurement systemLaser based measurement of flat geometries

Suitable for sheets and coils

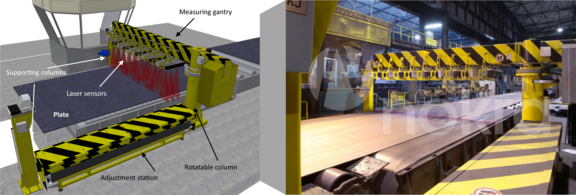

- Scalable portal solution: length up to 6000 mm, width up to 3200 mm, thickness starting from 0.5 mm

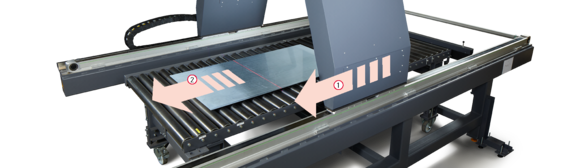

- Fast measurement process 0.5 m/s, e.g. 4 m sheet metal in 8 s

- Accuracy starting from ± 0.15 mm

- All shapes including any cutouts

- Suitable for production with high quality requirements and an interest in effective processes

- Quality proven (DIN/EN, ASTM), 100 % checked and documented

- Unmanned production due to fully automated inline measurement system

- Laser class 2, no special safety precautions required

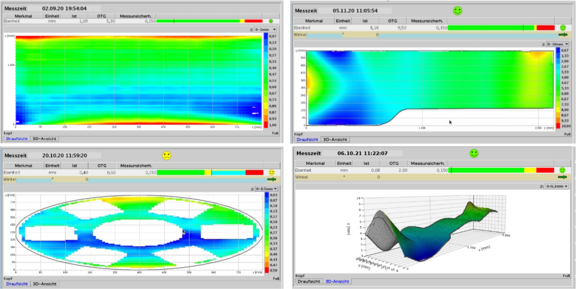

High-density measurement data

2D or 3D visualization

A 2D or 3D graphic shows the contactless measured flatness and contour of each sheet manufactured in the production line. After the passage it is directly shown on the control panel. Through feedback of the measurement results into the process management additional cost-intensive errors in the production are avoided.

Standard configuration of laser measurement system

- compact portal system, measuring device capable

- automatic monitoring according to MSA method 1

- E-cabinet (2100 x 1200 x 800 mm h x w x d) including control and evaluation IPC

- operator-PC (desktop version including mouse, monitor, keyboard)

- 15 m cable set (max. 80 m)

- signal inputs for safety-door and E-stop

- standard interfaces Profibus/Profinet, TCP/IP, UDP

- remote access via internet

- graphical display of results as 2D heatmap and 3D view

- graphical display of the measurement characteristics flatness, length, width

- data storage and management, storage capacity 4 TB

- history view of stored measurement results

- display and storage of warning and fault messages

Technical data

| Measurement width | 800 mm to 3200 mm in steps of 400 mm |

| Measurement length | scalable up to 6000 mm |

| Scan speed | max. 1 m/s |

| Material width | 50 mm to measurement width |

| Material length | 100 mm to measurement length |

| Material thickness | 0.5 mm to 250 mm (others on request) |

| Material shape | flat objects of any shape and any cutouts/holes |

| Material type | all non-transparent materials |

| Material surface | no restrictions, smooth or textured, reflective or matt |

| Material temperature | max. 80 °C |

| Measurement resolution height | 5 μm |

| Measurement resolution width | 10 μm |

| Measurement resolution length | 5 μm |

| Measurement accuracy flatness | +/- 0.025 mm (without flatness influence of the base) |

| Measurement accuracy width | +/- 0.15 mm |

| Measurement accuracy length | +/- 0.10 mm |

| Flatness evaluation | acc. to DIN EN ISO 12781; strip edge waviness acc. to DIN EN 10251; various other ruler evaluations |

| Measurement principle | laser triangulation (laser light-section sensors) |

| Laser class | 2 (no laser safety officer) |

| Laser wave length | 660 nm (red) |

| Laser life time (MTBF) | 80,000 h @ 20 °C |