Measuring in other dimensions

Typical rough plate metal, for instance for large pipes, pipelines, mobile cranes, ships and platforms for wind power plants with its dimensions of several 10 square meters has a total weight of several tons. The most frequent reason for reclamation is a flatness requirement which has not been complied with. The flatness of every manufactured metal plate in the production line is subjected to contactless inspection by a contactless flatness measuring system.

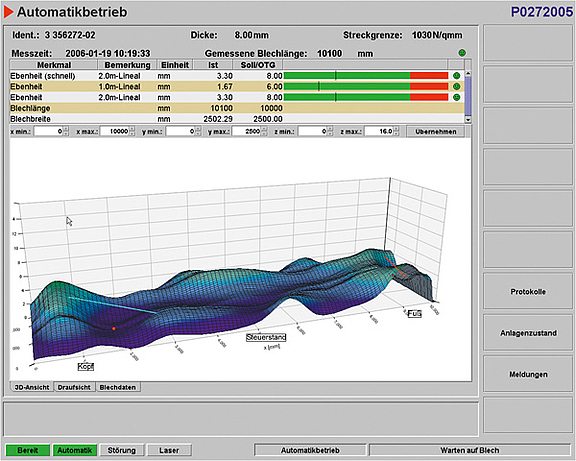

A 3-D presentation shows the measured flatness. After the passage it is directly shown on the control panel. Through feedback of the measurement results into the process management additional cost-intensive errors in the production are avoided.

nokra’s flatness measuring systems are fitted with an automatic function for adjusting and monitoring (measuring capability proof in accordance with DIN EN ISO 9001).

nokra flatness measuring means:

- automatic 100% measurement and seamless documentation

- automatic classification of the flatness defects

- optimization of the upstream production processes

- use also in hot strip manufacturing

- maintenance-free

- insensitiveness to extraneous light

- flexibility with regard to the different dispersion properties of the surfaces to be inspected

nokra's systems are used with high-precision single or multi-track thickness measurements of metal plate and strips, glass measurement (windscreens) and for inspecting brake disks.