The Triangulation

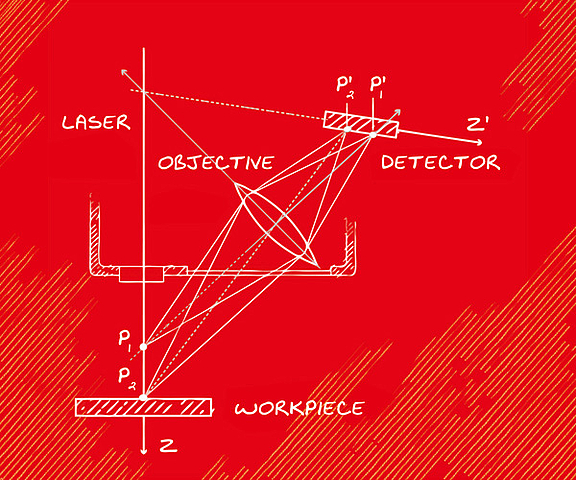

The laser triangulation determines the distance of an object from a reference level through a contactless process. Similar to a probe a triangulation sensor provides a one-dimensional measuring parameter. The laser beam is aimed at the workpiece. The laser light is scattered at the point of impact. An objective, which is aligned at an angle to the direction of arrival of the laser beam, images the light spot on a detector. The position of the imaged light spot on the detector is a measurement for the distance of the workpiece. The expansion of the laser triangulation to a two-dimensional measurement is the laser light sectioning process.

nokra was one of the first companies in Germany to successfully make the laser triangulation process suitable for inline inspection of geometric measuring parameters in industrial applications.

With this process nokra has specialized in measuring distance, thickness, profile and shape. nokra sensors are characterized by a high measuring frequency, a temporally precise synchronizable measurement and high dynamics with regard to the dispersion properties of the measured surface.