Thickness measurement for up to 2 m wide strips

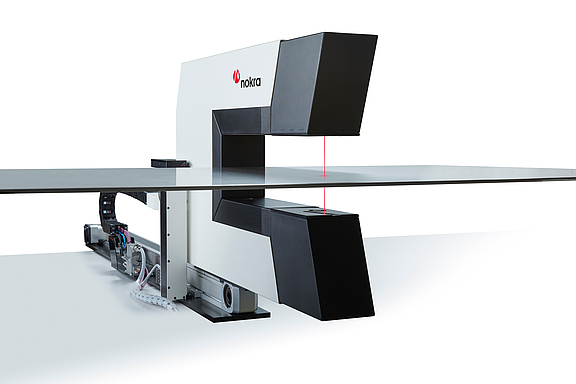

alpha.ti 5.0 / Laser measurement systemLaser based measurement of strips

For use in process and finishing lines

- easuring method suitable for thicknesses of any size independent of material composition

- Small measuring spot, high detail resolution

- Precise position information along and transverse strip direction

- High measuring frequency for speeds up to 2000 m/min with a measurement accuracy starting from ± 1.5 μm

- Fast and automatic adjustment of sensor sensitivity to any surface

- Patented drift compensation for the entire system

- Traceability due to automatic referencing on gauge blocks

- Automatic measuring equipment monitoring according to MSA method 1

- Laser class 2, no special safety precautions necessary

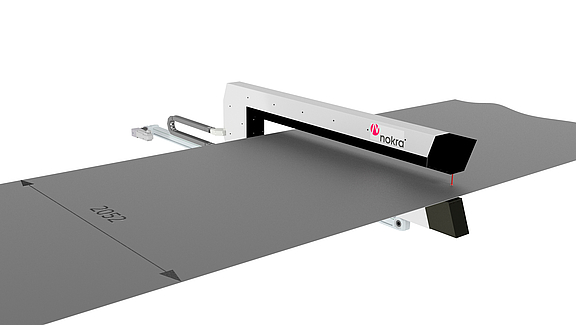

C-frame for cross profile measurement up to 2100 mm

C-frame versions, measuring depths: 500 / 1000 / 1500 / 2100 mm

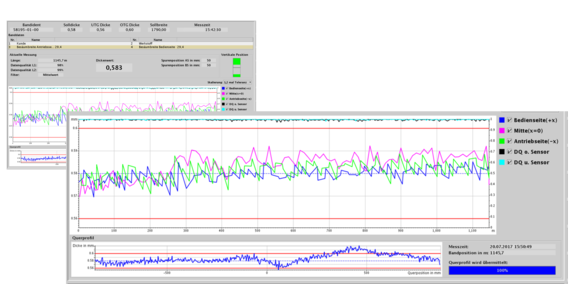

Patented drift compansation

The deformation sensor continuously records the distance between the two C-bars with a precision of 0.5 µm at the scanning frequency of the triangulation sensors. Any change is immediately compensated automatically. This allows C-frame designs with a measuring depth of more than 2 meters with consistent measuring accuracy.

Continuous measurement data acquisition - high sampling rate and resolution

Accuracy of measurement data

- Measuring accuracy is 0.01 % of the measuring range

- Repeatability is about a factor of 10 better than the measuring accuracy

- Three measuring ranges are available:

- 15 mm → Accuracy ± 1.5 μm → Repeatability ± 0.2 μm

- 25 mm → Accuracy ± 2.5 μm → Repeatability ± 0.4 μm

- 40 mm → Accuracy ± 4.0 μm → Repeatability ± 0.6 μm

Standard configuration- laser measurement system

- automatic drift compensation through real-time deformation sensor

- temperature independent sensor linearity

- automatic exposure time and laser power control

- sample measurement mode

- automatic thickness reference unit using standard gauge blocks

- sensor windows prepared for compressed air blow-off

- measuring device capable, automatic monitoring according to MSA method 1

- standard interfaces Profibus/Profinet, TCP/IP, UDP

- prepared for analogue signal interface

- user interface in national language

- remote access via internet

- E-cabinet (1000 x 600 x 400 mm h x w x d)

- 15 m cable set (max. 80 m)

- signal inputs for safety-door and E-stop

Technical data - alpha.ti 5.0

| C-frame | C-15 | C-25 | C-40 |

| Measurement principle | laser triangulation | laser triangulation | laser triangulation |

| Measurement window | 15 mm | 25 mm | 40 mm |

| Linearity | ± 1.5 μm | ± 2.5 μm | ± 4 μm |

| Resolution | 0.24 μm | 0.39 μm | 0.62 μm |

| Repeatability | ± 0.2 μm | ± 0.4 μm | ± 0.6 μm |

| Measurement frequency | max. 67 kHz | max. 67 kHz | max. 67 kHz |

| Integration time | 0.5 μs - 1000 ms | 0.5 μs - 1000 ms | 0.5 μs - 1000 ms |

| Laser class | 2 (no laser safety officer) | 2 (no laser safety officer) | 2 (no laser safety officer) |

| Laser wave length | 660 nm (red) | 660 nm (red) | 660 nm (red) |

| Measurement spot | 50 μm | 50 μm | 50 μm |

| Laser life time (MTBF) | 80000 h @ 20 °C | 80000 h @ 20 °C | 80000 h @ 20 °C |

| Measurement depth from strip edge | 500 / 1000 / 1500 / 2100 mm | 500 / 1000 / 1500 / 2100 mm | 500 / 1000 / 1500 / 2100 mm |

| C-frame width | 144 mm | 144 mm | 144 mm |

| Traversing speed | 0.25 m/s | 0.25 m/s | 0.25 m/s |

| Material type | all non-transparent materials, surface and alloy independent | all non-transparent materials, surface and alloy independent | all non-transparent materials, surface and alloy independent |

| Material speed | > 0 m/min; ≤ 3000 m/min | > 0 m/min; ≤ 3000 m/min | > 0 m/min; ≤ 3000 m/min |

| Material temperature | ≤ 100 °C, others with active tempering | ≤ 100 °C, others with active tempering | ≤ 100 °C, others with active tempering |