Products

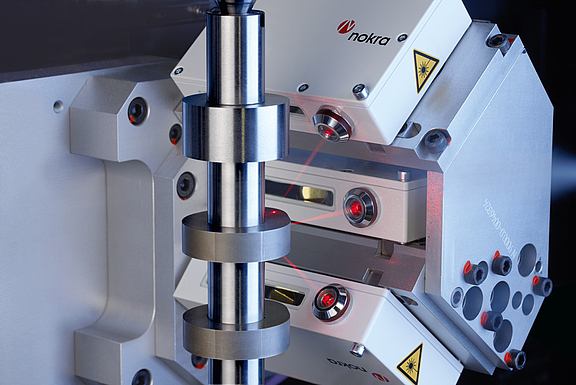

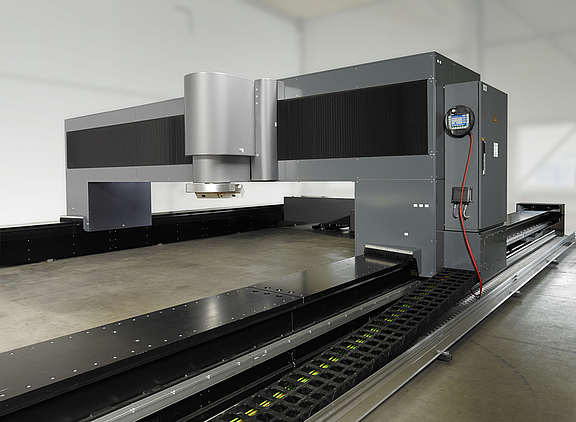

We develop, produce and sell laser measuring systems for automatic inline inspection of geometric features of products such as thickness-gauges for the steel- / aluminium production, flatness-gauges for heavy plates, plate- and coil production (aluminium-, steel- and NF-metals). Our product range also includes curvature-measurement systems for windshields of glass. Our high-precision measuring systems are used in the automotive, glass and metal industry throughout the whole world. The objects inspected are components of vehicles, such as camshafts and crankshafts, axle brackets, windscreens, and rolled products in the steel and aluminum industry.

nokra has installed well over 250 inspection systems. Almost 2,500 laser sensors are used in the plants.

We are willing to take on demanding challenges. The pooling of the necessary scientific and technical disciplines of our staff creates a great potential for new ideas and produces innovative and effective solutions.

Whether this involves a shaft test system, flatness and thickness measurement or special systems, you can expect the following value-adding activities from us:

- developing and manufacturing the nokra laser sensors

- planning and manufacturing the electrical engineering of the plant

- developing the software and algorithms for controlling and operating the measuring systems, for evaluating the laser measurement data and for visualizing and storing the measurement results

- construction and assembly of the complete mechanism of the plant, as well as commissioning and servicing it