Sensors for the production

nokra sensors have been developed for direct use in the production line. This enables the user to exploit a considerable potential for monitoring, guiding and optimizing its manufacturing process. This increases productivity and efficiency in the series production.

nokra sensors are preferably used for automatic inspection of geometric features of products in the automotive and steel industry. The objects inspected are components of vehicles, such as camshafts and crank-shafts, and rolled products in the metalworking industry.

nokra sensors record and evaluate geometric parameters quickly and precisely. Different and changing measuring surfaces are accurately and surely recorded by the rapid control of the laser beam source and the detector.

Design and concept

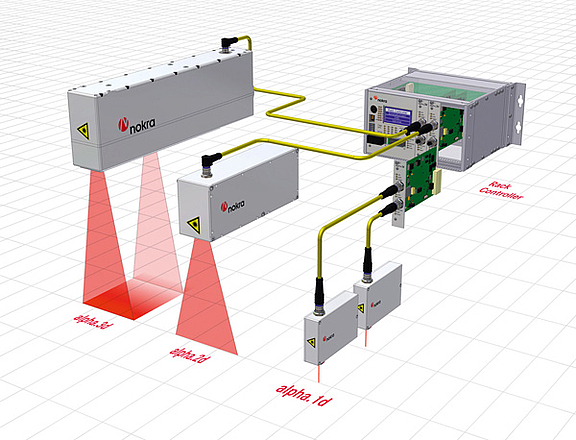

The alpha sensors are connected via a central rack controller with a superordinated control level. A touchscreen is available for operating the sensors.

Distance and light sectioning sensors – alpha.1d, alpha.2d and alpha.3d – are combined through the rack controller to form a client application. The rack controller controls and synchronizes the measurements of the sensors.

The measured values are issued via standard interfaces, for instance Ethernet or analog via the issuing module of the rack controller.