Efficient process management — inline and contactless

The achieved progress and the high speed of developments ensure that laser measuring technology is already revolutionizing inline inspection of geometric sizes today. Flatness, straightness, profile, thickness and width are typical inspection parameters, which are optically measured and hence contactlessly measured directly in the production flow - that is the key competence of nokra.

Our measuring systems inspect seamlessly and automatically in the production cycle. Contactless thickness gauges for strips and plates, or fully automatic flatness inspection systems can be used for the process controlling of quality steel or in the aluminium production. Camshaft inspection machines used in the automotive industry and contour measuring systems for the windshields of automobiles provide an insight into our product range. The results are objective and traceable inspection data, which are provided without any influence of the operator. The automatic feedback of the measured values in the production process increases productivity and efficiency.

News

Solid forming: Cold dimension prediction and tool evaluation at the production line

Formed parts at temperatures of up to 1200 °C are measured and checked against cold dimensions within a few seconds.

Presentation given at IMU Automation Working Group

As one of six specialist presentations, Günter Lauven contributed to the discussion on automation solutions in the forming industry.

Laser measuring cell for forged parts presented at IMU-Hatebur user meeting

The agenda included topics for optimizing process and energy efficiency. We presented the possible applications and advantages of the laser measuring…

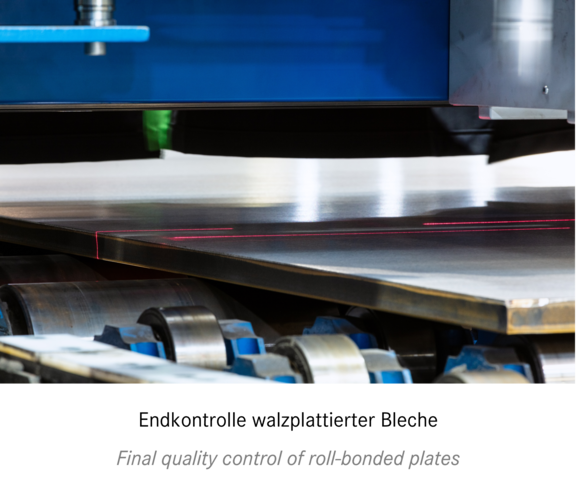

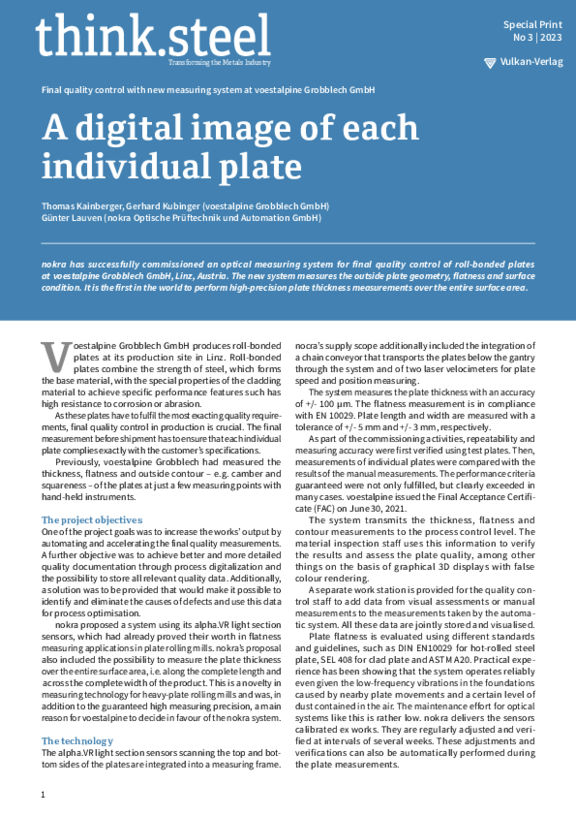

A digital image of each individual plate

At voestalpine Grobblech GmbH, Linz, an optical measuring system for the final quality control of roll bonded plates has been commissioned. It…