nokra has successfully commissioned an optical measuring system for final quality control of roll-bonded plates at voestalpine Grobblech GmbH, Linz, Austria. The new system measures the outside plate geometry, flatness and surface condition. It is the first in the world to perform high-precision plate thickness measurements over the entire surface area.

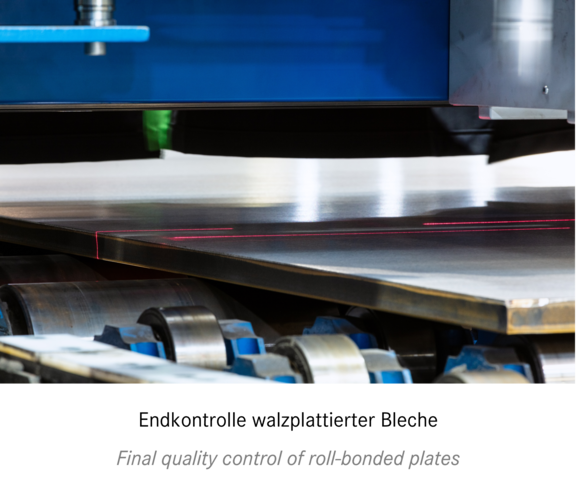

Voestalpine Grobblech GmbH produces roll-bonded plates at its production site in Linz. Roll-bonded plates combine the strength of steel, which forms the base material, with the special properties of the cladding material to achieve specific performance features such has high resistance to corrosion or abrasion.

As these plates have to fulfil the most exacting quality requirements, final quality control in production is crucial. The final measurement before shipment has to ensure that each individual plate complies exactly with the customer’s specifications.

Previously, voestalpine Grobblech had measured the thickness, flatness and outside contour – e.g. camber and squareness – of the plates at just a few measuring points with hand-held instruments.